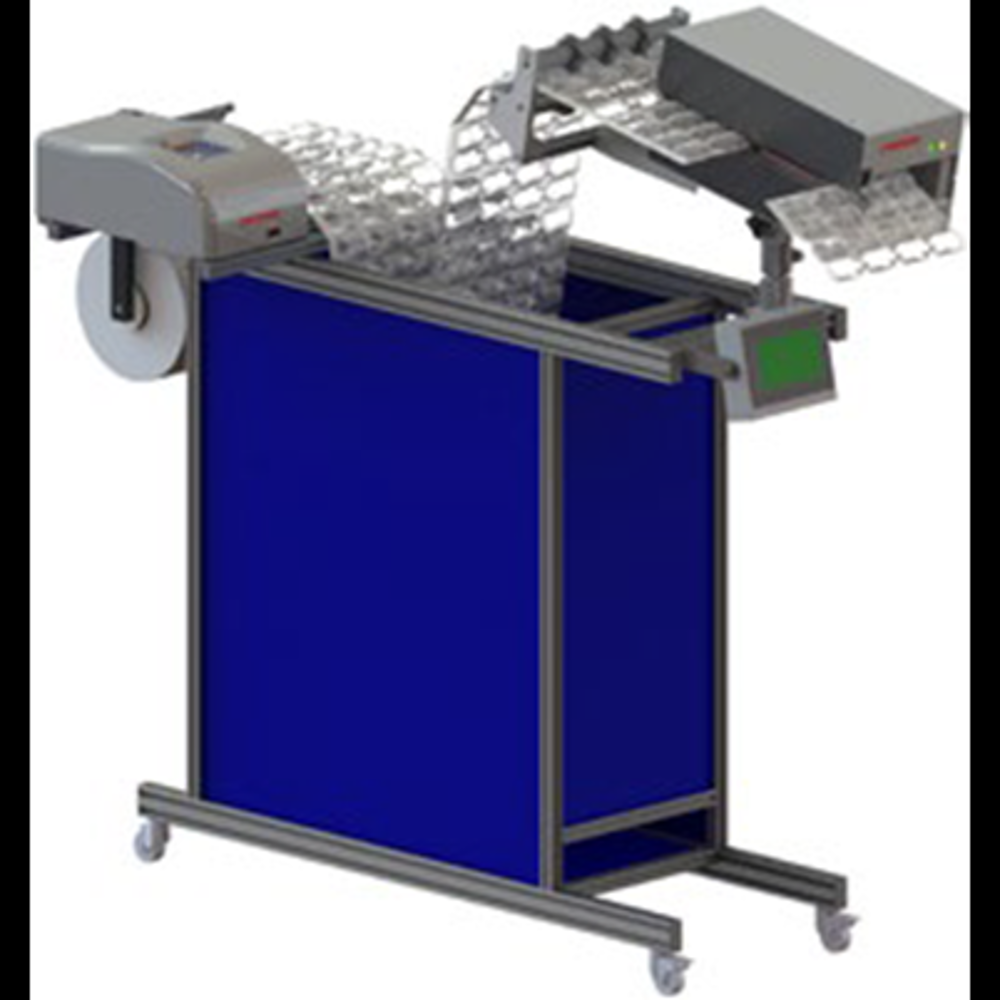

Airpad Smart Fill System

Automatically detect the right number of void fill pouches for your cartons

FROMM's new revolutionary Airpad Smart Void Fill System will revolutionise how your dispatch department work.

The new Smart Void Fill System calculates the optimum number of air cushions for each carton. The laser eye will scan the box and determine the optimal number of cushions for the box to ensure the contents will be protected during transit.

The Smart Void Fill System features a large touch screen operating panel, wireless for easy integration, three operating modes, manual with foot pedal or voice control.

It can produce 60m of void fill per minute, making it a must for your packaging area.

Two Year Warranty

Simulation Testing

5 Star Rated

Environmentally Friendly

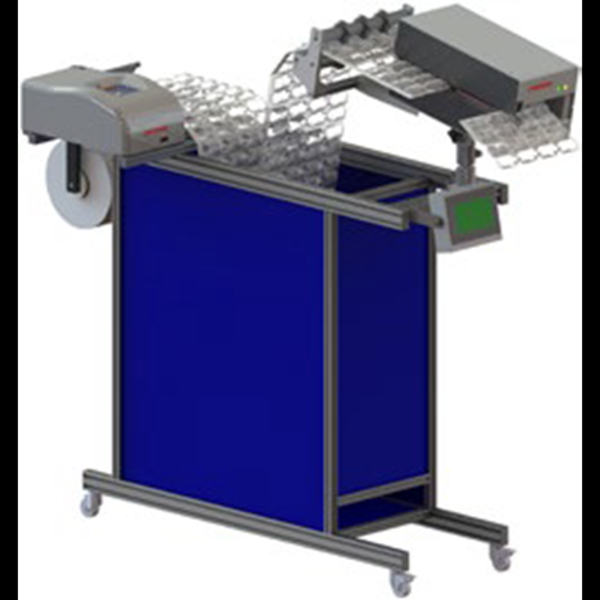

Features

- Calculates the optimum number of air cushions for each carton.

- Large touch screen operating panel, wireless for easy integration

- Three operating modes

- Manual with foot pedal or voice control

- Semi-automatic with pre-defined lengths to choose from the touch panel

- Automatic replenishment of a pre-set number of cushions

Benefits

- Dispense pre-separated cushions at arm’s length of the operator for optimum working conditions

- The high speed Airpad Shooter can produce 60m of void fill per minute.

- The laser eye can scan up to 20 cartons per minute

- Reduces product damages by ensuring the carton has the right amount of void fill protection

Technical Specifications

240 V

3.5 Kg (without options)

25.5 Kg (without options)

Up to 20 cartons per minute

60 m per minute

Our void fill machines are capable of producing high-yield void fill on demand, making them ideal for warehouses and businesses of all sizes. In line with sustainable practices, many of our void fill options use recycled paper as an alternative to plastic, providing eco-friendly solutions for packaging needs. These materials are 100% recyclable, reducing the need for complex waste separation at the end of use.

Reuse: While void fill materials are generally single-use, businesses can explore reusing leftover paper-based fill for internal packaging needs or storage solutions before disposal, extending its usefulness in the packaging cycle.

Reduce: FROMM’s void fill machines use air-filled materials, significantly reducing the amount of conventional filler needed. By producing void fill on demand and utilising air as a filler, businesses can minimise material waste and packaging costs, all while reducing reliance on heavier, less sustainable packing materials.

Recycle: FROMM’s paper-based void fill is made from recycled materials and is 100% recyclable. At the end of its lifecycle, businesses can easily recycle these materials along with other paper products, simplifying waste management and supporting circular packaging solutions.

Let's get your question packed up.

Fill in your details below, and one of our packaging experts will be in touch with a solution. Got a list of questions? Great, they love a chat.