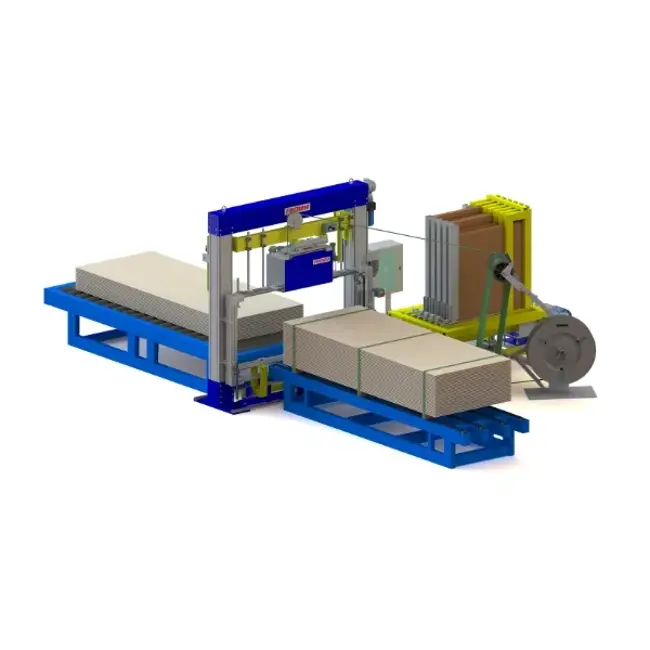

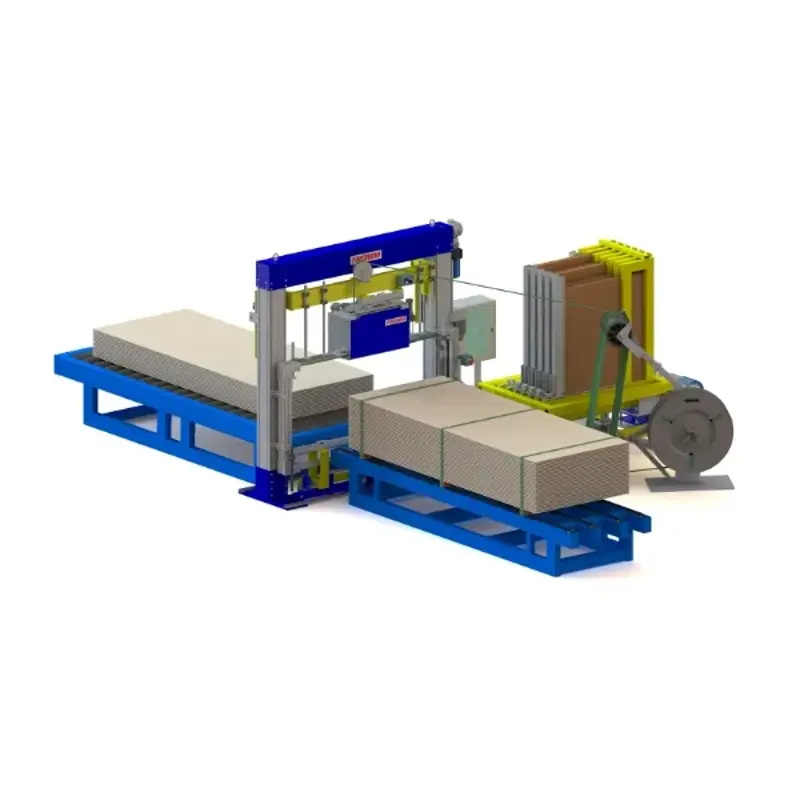

Automatic Inline Top Seal Strapping Machine - PM1 Series

Ideal for timber, logistics, bricks and metals with lots of modular options.

- PET or steel strap

- Base model with a range of custom options

- Suitable for paper, corrugated cartons, beverage containers, timber, tiles, bricks, blocks, steel & aluminium (ingots, pipes, tubes & coils)

- View machine specifications and options >>

Two Year Warranty

Simulation Testing

5 Star Rated

Environmentally Friendly

Features

- Top seal strapping head

- Suitable for any FROMM PET or Steel strapping head

- Siemens controls and touchscreen

- On-screen fault finding

- Modular with a range of options

- Every machine built for customer specific requirements

Benefits

- High production capacity

- Extensive customisation and options available

- Designed for continuous operations

- Manual intervention eliminated

- 150,000 cycle service intervals

- FROMM 2 year warranty

Specification

Dependent on conveyors

Unlimited

Friction, up to 85% of strap breaking strength

0.50 - 1.00 mm

18000 Newtons

0.4 mm - 1.35 mm

12 - 19 mm

7000 Newtons

105 mm / second

Options

Fixed or gated

Fixed or floating

1000 - 5000 kg

Standard, jumbo or superjumbo

Top corner applicators, bottom corner applicators

Magazine or robot

Automatic head cleaning

Fixed track or bayonet to strap through the pallet

FROMM plastic strapping is manufactured in one of our global production centres using almost 100% recycled polyester resin. Extruded on one of our state of the art production facilities, FROMM uses RPET resins with high IV values. Strapping can be offered on small 20 kg coils up to 250 kg super jumbo rolls.

Reuse: PET strap is not generally reused in its original form, but it can contribute to a sustainable cycle. Once the strapping has served its purpose, it can be collected, recycled, and transformed into new, high quality products, to minimise waste.

Reduce: By choosing lightweight PET strap, designed for our machines and tools, businesses can lower transportation emissions and decrease material usage, contributing to a more sustainable packaging solution.

Recycle: Fully recyclable, our PET strap supports a circular economy. After use, it can be processed into new products, reducing landfill waste and promoting sustainability.

Strap all your questions together and we will get an answer for you

Fill in your details and one of our packaging experts will come back to you shortly