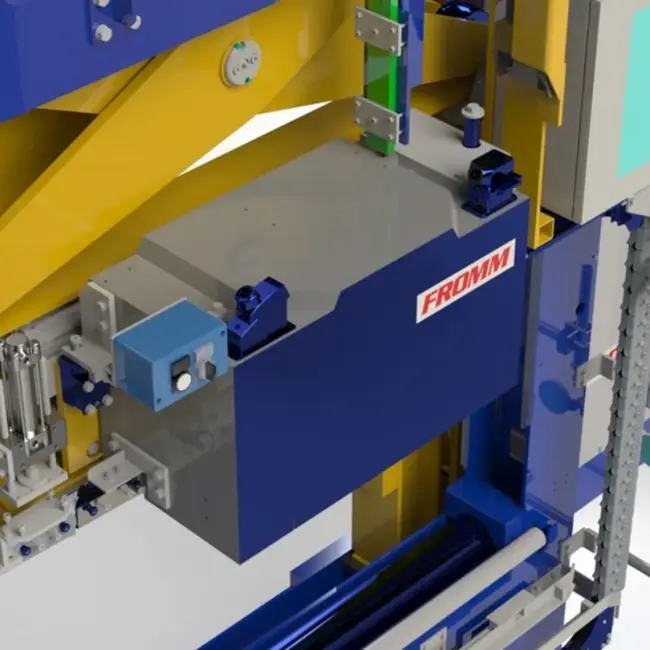

Bespoke Polyester Strapping Machine Options

For automated strapping solutions, most projects demand meticulous detail and custom design. FROMM tailors designs to seamlessly fit into both existing and new packing lines, minimising disruption and adapting to available structures. We can retain our award-winning strapping heads in the design and can incorporate specific customer requests. The result is always a system that straps and unitises products according to customer standards while upholding our manufacturing quality.

With the option for both steel and plastic strapping heads, FROMM is uniquely positioned to deliver the ideal solution to meet the demands of the Australian market. Contact us today to discuss a tailored solution for your business.