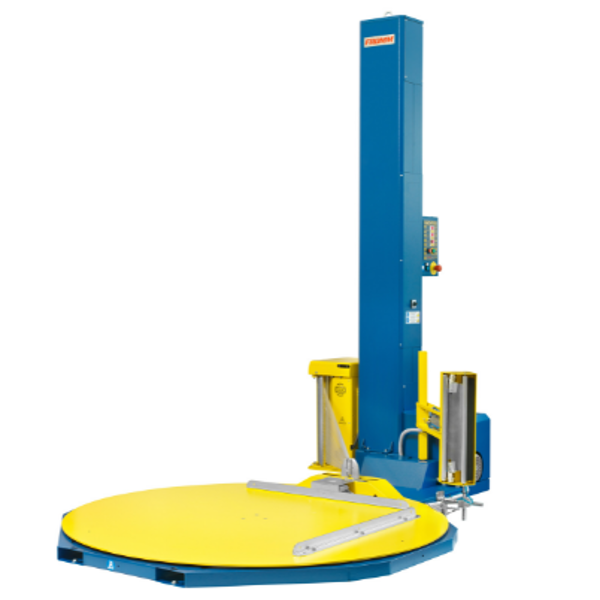

FS380A Automatic Wrapping Machine

Remote control Pallet Wrapping Machine

Introducing the new FS380A Wrapping Machine. With easy operation, this pallet wrapping machine makes it the ideal solution for sites with a variety of operators and products.

The Wrapping Machine features a remote control start, film blower, and heat sealer for no tails and dags which will revolutionise the Australian Packaging Industry. Easy to use with just a one-touch operation, you can be up and running in no time at all.

At Fromm Packaging, we understand the importance of dispatching pallets with no dags to ensure they are not rejected at large retail distribution warehouses. The FS380A Wrapping Machine is designed with a film blower and heat sealer ensuring the excess film is stuck to the pallet. This is a game-changer in the Australian packaging industry.

Two Year Warranty

Simulation Tested

5 Star Rated

Environmentally Friendly

Features

- Remote control operation

- Film blower and heat sealer for no dags and tails

- Automatic pallet height sensor

- Fully programable wrapping patterns

- 200% powered pre stretch film delivery system

Benefits

- Cost-effective remote control wrapping machine on the market

- Supported by our on-site mobile service team

- Simple and easy to use

- No prior experience needed

- Labour saving alternative to hand wrapping

- Simple plug & play operation

- Optimises supply chain operations

- Rent or purchase

Machine Specification

Low

0 - 200 %

240 V

2000 Kg

2200 mm

5 - 12 RPM

1800 mm

6 Bar

Options

Available

Available

Up to 2700 mm

Plastic stretch wrap is an integral material for safe and secure pallet load containment. FROMM’s high-quality, tear-resistant stretch wrap, including our Verde stretch films made from a 30% blend of recycled materials and 70% virgin materials, stretches further than ever—capable of significant stretch without compromising product integrity for suitable products. Bundled with our wrapping machines, our customers use less film, resulting in reduced packaging and waste disposal costs. For example, our Forza range offers up to 250% stretch, effectively reducing single-use plastics, making it an ideal choice for businesses focused on sustainability. The enhanced stretchability means less material is required overall, and precise product usage enabled by our wrapping machines minimizes unnecessary waste.

Reduce: Our Forza 12um film significantly reduces the amount of plastic needed, providing the same performance as thicker films. This helps lower plastic consumption and supports businesses in meeting their sustainability goals.

Reuse: While most stretch wrap is designed for single use, we encourage reusing leftover wrap for smaller, in-house applications where feasible, helping extend its life before disposal.

Recycle: Our Verde stretch films are made with 30% post-consumer recycled (PCR) material and are fully recyclable under the recycling code LLDPE (4). We promote proper recycling practices and work with clients to ensure that used wraps enter the recycling stream whenever possible.

THE ORIGIN OF ÆOLUS

Æolus is the god of wind from Greek and Roman mythology. He was a son of Poseidon who was appointed by Zeus as the keeper of the winds: Boreas the north wind, Notos the south wind, Euros the east wind and Zephyrus the west wind.

Æolus kept these winds locked up in a cave and could send them out at will to bring wind.

The FROMM Æolus system is available on all FROMM 2000 series wrapping machine

HOW DOES IT WORK

The new FROMM patented Æolus Air technology, attaches the film to the product by directed airflow at the start of each wrapping cycle. After the automatic cutting of the film at the end of the wrapping cycle, the loose film end is blown / fixed against the package by the same air stream.

This completely eliminates the need to attach film to the pallet by hand and enables the user, after placing the pallet, to run the entire selected wrapping program automatically. The Æolus package includes the film blowing unit, remote control and automatic film cutting device.

Need the perfect packaging solution? Let's wrap this up!

Share your details below, and our packaging experts

get back with the solution .