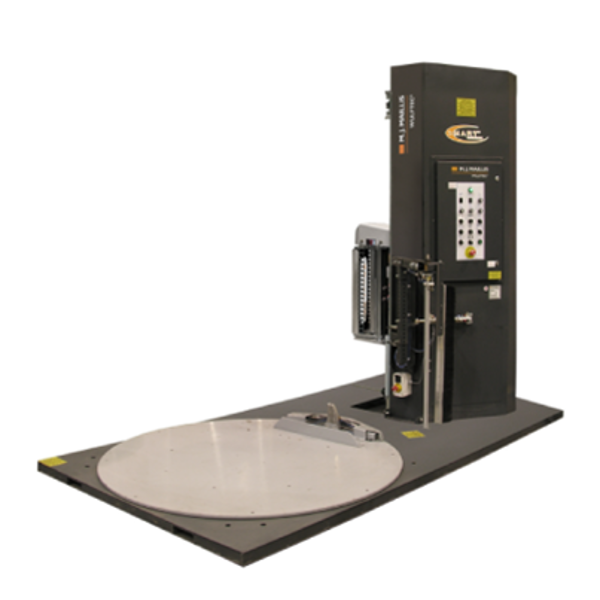

Wulftec SMLPA200 Stretch Wrapping Machine

Social distancing is easy with a SMLPA200 Wrapping Machine remote control start feature

The Wulftec SMLPA200 Automatic Stretch Wrapping Machine is the industry’s most robust standalone wrapping machine. FROMM has now upgraded our base model in Australia with the standard plus panel. Built big, strong and tough the SMLPA200 allows the forklift operator to place the pallet, and start the cycle with remote control. This wrapping machine will ensure your warehouse staff meet the new government social distancing laws. The operator never needs to leave the forklift, meaning no human contact, contactless packaging area, creating a safe work environment for your staff with lower WH&S risks.

Capable of wrapping up to 160 pallets per day and with up to 250% power pre-stretch it can generate one metre of the film on the roll to 3.5 metres on the pallet. Saving you thousands per year on stretch film. The SMLPA200 is the most productive and cost-effective wrapping machine on the market.

The new standard plus panel features a touch screen, 3 pre-set wrap patterns, alarm readout and the ability to password protect wrapping patterns.

Two Year Warranty

Simulation Tested

5 Star Rated

Environmentally Friendly

Features

- Patented cut/clamp/wipe system

- 100% all steel construction

- Easy access to all components

- AC variable frequency drives and motors

- Local parts availability - most are non-proprietary

- Allen Bradley PLC and AC motors

- NO-THREAD® powered pre-stretch carriage

Benefits

- Automatic pallet height detection sensor

- Cut and wipe to secure film

- Soft start and stop for light loads

- Fully adjustable wrap programs

- Automatic operation by remote control

- Capable of wrapping up to 160 pallets per day

- 250% film stretch - 1 metre film = 3.5 metres

- FROMM 2 year warranty

Machine Specification

2275 kg

2032 mm

16 RPM

1470 mm (octagon)

Low

200%

240 Volt

3 CFM @ 80 PSI

Options

Up To 3200 mm

Available

For Wet Or Corrosive Environment

Rust Protection Coatings Available

Plastic stretch wrap is an integral material for safe and secure pallet load containment. FROMM’s high-quality, tear-resistant stretch wrap, including our HYBRID stretch films made from a 30% blend of recycled materials and 70% virgin materials, stretches further than ever—capable of significant stretch without compromising product integrity for suitable products. Bundled with our wrapping machines, our customers use less film, resulting in reduced packaging and waste disposal costs. For example, our Forza range offers up to 250% stretch, effectively reducing single-use plastics, making it an ideal choice for businesses focused on sustainability. The enhanced stretchability means less material is required overall, and precise product usage enabled by our wrapping machines minimizes unnecessary waste.

Reduce: Our Forza 12um film significantly reduces the amount of plastic needed, providing the same performance as thicker films. This helps lower plastic consumption and supports businesses in meeting their sustainability goals.

Reuse: While most stretch wrap is designed for single use, we encourage reusing leftover wrap for smaller, in-house applications where feasible, helping extend its life before disposal.

Recycle: Our HYBRID stretch films are made with 30% post-consumer recycled (PCR) material and are fully recyclable under the recycling code LLDPE (4). We promote proper recycling practices and work with clients to ensure that used wraps enter the recycling stream whenever possible.

Need the perfect packaging solution? Let's wrap this up!

Share your details below, and our packaging experts

get back with the solution .